Remote Network Management in Oil and Gas Production

Remote Network Management in Oil and Gas Production Applications

Challenge:

When crucial network devices at remote oil rigs or production platforms suddenly cease to respond to commands, tech support personnel need a means to correct the problem at once. Any delay in restoring network communication with remote oil industry facilities can quickly result in production outages and unnecessary downtime. In order to maximize productivity and minimize downtime, network problems must be resolved as soon as they are detected, without waiting for support personnel to travel to the remote site.

When network issues disrupt access to important devices and services at distant drilling rigs and production platforms, NOC personnel need quick, secure remote access to power reboot and console port command functions on remote, networked devices in order to restore communication and avoid outages that interfere with productivity. In order to allow support personnel to deal with network emergencies at remote drill rigs, support vessels and production platforms immediately, administrators need an out-of-band management solution that provides the following capabilities:

- Reboot Remote Network Elements

- Access Console Port Command Functions on Remote Devices

- Enable Power Redundancy for Single Corded Equipment

- Provide Secure Remote Access via Network plus Dial-Up, Satellite and Cable Modem

- Allow Out-of-Band Access when the Primary Network is Down

- Monitor, Report and Log Conditions and Events at Remote Site

- Provide Centralized Enterprise Management Interface

Solution:

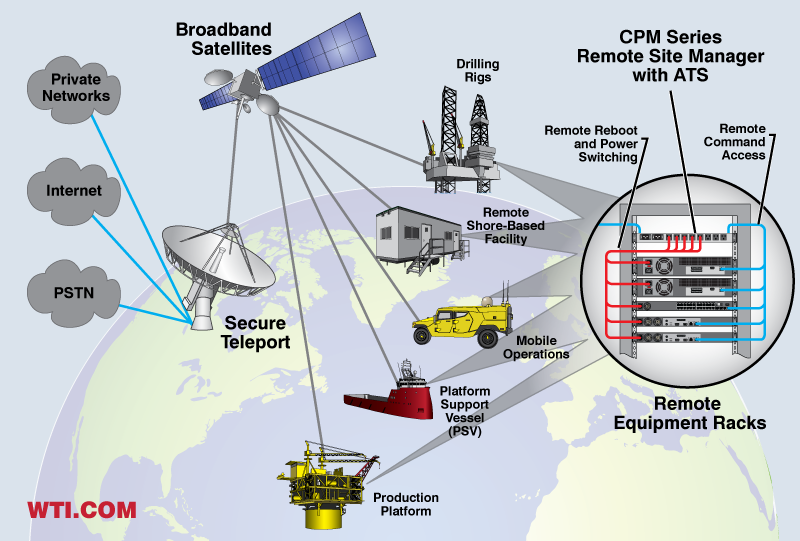

In oil and gas production facilities, WTI‘s CPM Series Remote Site Manager can be used to provide administrators and tech support personnel with remote access to power switching, reboot and console port command functions at various types of remote network equipment sites. The configuration shown in the illustration above allows network technicians to quickly establish a secure connection to the CPM unit via secure broadband satellite and then manage network elements at drilling rigs, production platforms, support vessels and other remote oil and gas related facilities.

When a network element at one of these remote facilities becomes unresponsive, support personnel can then employ the CPM to reboot routers, firewalls and switches at distant sites or access console port command functions on other devices in the remote equipment rack. In some applications, the remote power switching capabilities provided by the CPM can also be used to power down devices that are not in use or switch on auxiliary devices based on need.

In addition to providing remote reboot and console access capabilities, the CPM Remote Site Manager also includes monitoring and alarm functions that enable administrators to keep track of conditions at distant drilling rigs and support operations. When unusual current consumption levels, extreme temperatures, excessive invalid access attempts and other significant events are detected at a remote site, the CPM can provide immediate notification via email, text message or SNMP trap, or automatically perform user-defined actions such as shutting down nonessential devices or locking down network access. The CPM can also log alarm events, providing support personnel with an audit trail that can be used to track the source of recurring problems and events.

Obviously, security is an important concern in any remote network management application, and this is especially true in the oil and gas industry where unsecured network devices can potentially result in costly downtime and environmental mishaps. All WTI remote management products utilize an embedded FIPS-140-2 cryptographic module to provide the highest level of security available, while also allowing quick, easy access for authorized users. WTI remote management products also support secure communication protocols such as SSH and HTTPS as well as encryption formats such as FIPS and SSHv2 to ensure that data sent to and from the CPM unit remains protected from interception by unauthorized users. In order to verify the identity of each potential user, WTI products also feature popular authentication protocols, such as TACACS+, LDAP, Kerberos and RADIUS and a callback security feature to protect access via modem.

Results:

The remote, out-of-band management capabilities and power fallback functions provided by the CPM provide the perfect fit for managing network elements at off-shore drilling rigs and production platforms as well as pipeline monitoring applications and tanker communications systems. In any petroleum industry application that requires management and maintenance of network devices at far-flung locations, the CPM can provide administrators with a valuable tool for both keeping tabs on conditions at the remote site and for dealing with emergencies as they arise.

In larger network deployments that require more than the 8 switched outlets and 8 RJ45 console, WTI’s DSM series console servers, VMR series metered switched PDUs, NPS series switched PDUs, NBB series vertical format switched PDUs and PTS series power transfer switches can provide a perfect solution. In cases that require remote access to more than eight console ports, WTI’s DSM series console servers can provide secure, out-of-band communication for up to 40 console ports. Likewise, in applications that exceed the power switching and reboot capabilities supplied by the CPM, WTI’s VMR, NPS or NBB series switched PDUs can provide up to 20 remotely switched outlets. And for larger power failover applications, our PTS series Automatic Transfer Switches can provide power redundancy for up to 14 single corded devices.

Request a free demo

WTI products can be demo'd through any of the following options: